Cladding Fixings

All metal fixings - nails, screws, concealed support systems, bolts and accessories shall be made from corrosion resistant material whether the cladding board surface is to be finished with a coating or left unfinished to weather.

| Suitable metals | Unsuitable metals |

| Stainless steel - Austenitic grade | Aluminium |

| Silicone bronze (suitable for shingles/shakes ONLY) | Electro plated steel |

| High performance coated steel | Brass |

| Hot dipped galvanised copper (BS7371:6 min) |

This section contains advice on connecting timber to timber only.

Some species of timber can emit acids (such as acetic acid) which have corrosive effects on certain metals.

-

For Western Red Cedar, Douglas Fir and some hardwoods, only use stainless steel or specialist coated fixings otherwise the reaction to iron can cause permanent black spotting and corrosion staining of the surface (see image).

-

The use of dissimilar metals on the same fixing point should be avoided to minimise the risk of galvanic corrosion. When using galvanised fixings care must be taken to prevent the coated surface being damaged by hammers or driver bits as this can lead to corrosion of the mild steel below.

Screws or nails?

The risk of timber splitting or fixings pulling through is minimised by the way boards are fixed to the battens. Common practice is to install timber cladding using ‘face fixed’ nails or screws – fixing the cladding to the batons behind, through the front face of the timber cladding.

Softwood - for most cladding softwoods, ring shank nails are recommended.

Hardwood - on hardwoods and some higher density softwoods (ie. Siberian Larch, Douglas fir), the use of screws is recommended. For such dense species with a potential for splitting around fixing points, the pre-drilling of pilot holes (70% of shank diameter) should be carried out. On green oak, to take up the shrinkage that will occur, it is important to use minimum 4mm oversize pilot holes with washers or fixings with larger heads.

Where concealed fixing is required then boards may be back fixed to counter battens or installed using a proprietary metal fastening bracket or support system.

Cladding fixing positions

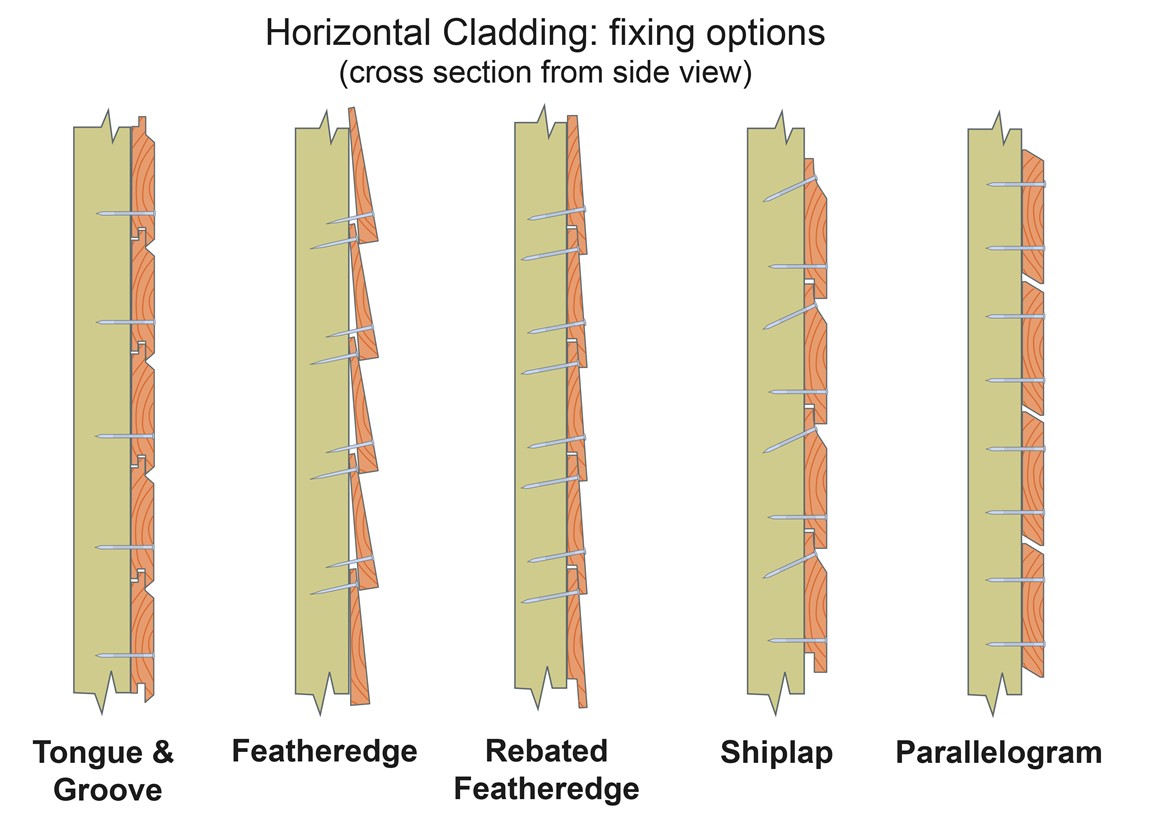

How you fix your cladding depends on several factors including the profile and size of board, the timber species and the preferred aesthetic. Here are some standard, generic guidelines (consult board manufacturer if specialised profile and/or modified wood product):

- Battens should extend the full width of the boards either side.

- Where boards abut, use a second batten to provide adequate support.

- Pre-drill fixing points at board ends to prevent splitting.

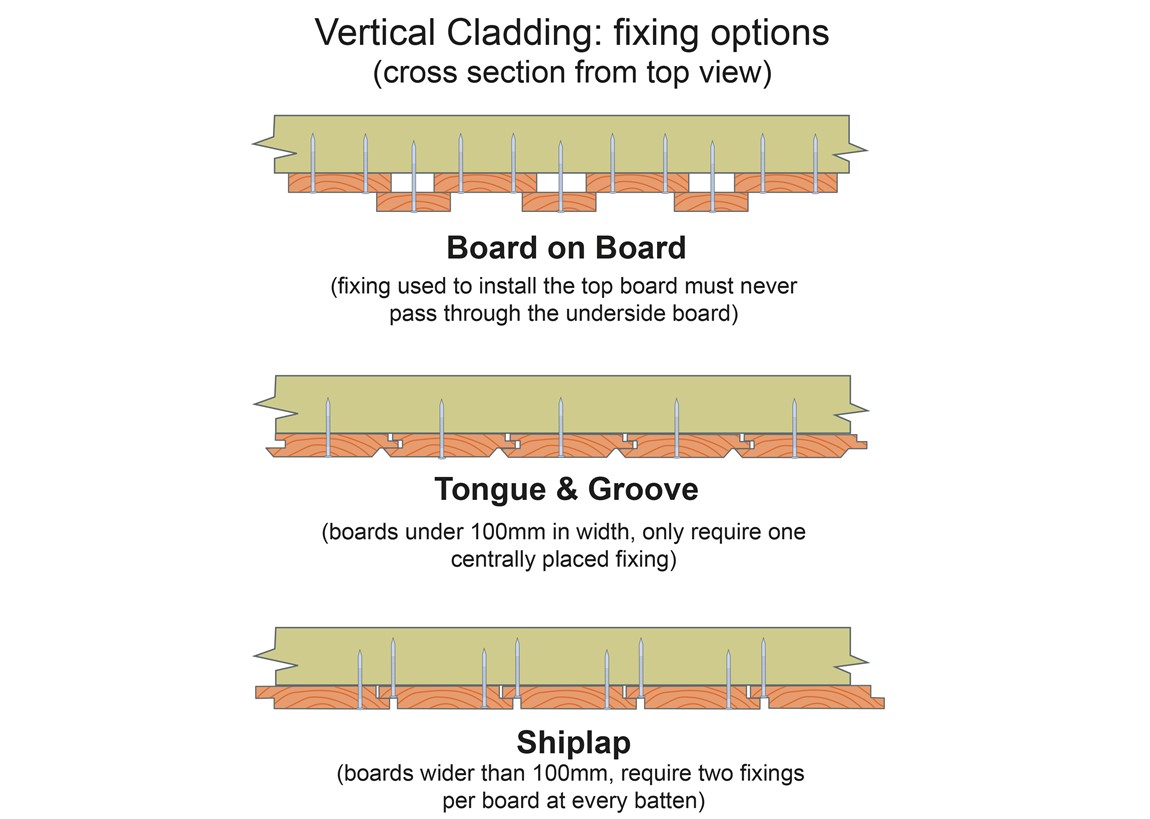

- For boards 100mm and wider, use two fixings per board at every batten.

- On boards under 100mm in width, use one centrally placed fixing.

- Position fixing 25% in from each side and a minimum of 20mm in at board ends (depending on shaft diameter and timber species) and pre-drill to avoid splitting where necessary.

See our FAQ for further detail: How do you prevent timber cladding boards from splitting when fixing?

- Where the board on board style is used, the fixing used to install the top board must never pass through the underside board. This is because any movement in the top and bottom boards caused by seasonal moisture changes and expansion and contraction will result in splitting.

- 'Secret fixing' systems and techniques can be used to hide the visibility of the fixing – suitability depends on the timber species, profile (tongue size) and installation orientation. Concealed fixing systems are best used in the prefabrication of cladding panels.

Application

-

Pneumatic fixing guns should be used with care to ensure the surface is not affected by impact damage or the fixings driven below the surface. Many fixings supplied for gun application come with off centre D shaped heads and designers should satisfy themselves that this is aesthetically acceptable.

-

For screw fixing, hand held 'impact' type screw drivers are best as these are less likely to damage the wood or the drive recess and will insert the screw at optimum speed and prevent the coating burn associated with high speed power drivers.

-

All fixings should finish flush with the surface and should not be punched or countersunk because this can result in splits and surface staining. As such it is important to ensure that the cladding moisture content is around 16% at time of installation to avoid shrinkage that would leave fixings proud of the surface.

Nail and Screw Sizing

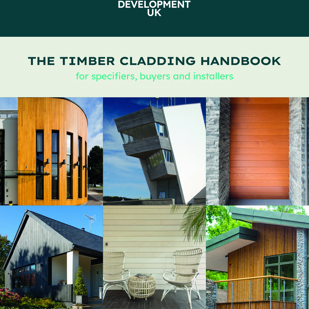

For details of nail and screw sizes for fixing cladding boards to battens, battens to counter battens and battens to a backing wall, please refer to our Cladding Handbook - free to download HERE.

OVERVIEW

- All metal fixings should be made from corrosion resistant materials

- Through the face fixing (face fixing) is the most secure way to install timber cladding

- Use two fixings per board / batten intersection placed at quarter points and one fixing for cladding boards less than 100mm wide

- All fixings should finish flush with the surface

- Nail and screw dimensions should be relative to board thickness / density

- Take measures to prevent splitting around fixing points e.g. for dense species prone to splitting pre-drill pilot holes 70% of shank diameter. See FAQ on both this and the next point.

- Position fixing 25% in from each side - a minimum of 20mm from board ends.

- Timber cladding should have a moisture content of 16% ± 4% at time of installation (unless using green oak - specialist knowledge required)