How do you prevent timber cladding boards from splitting when fixing?

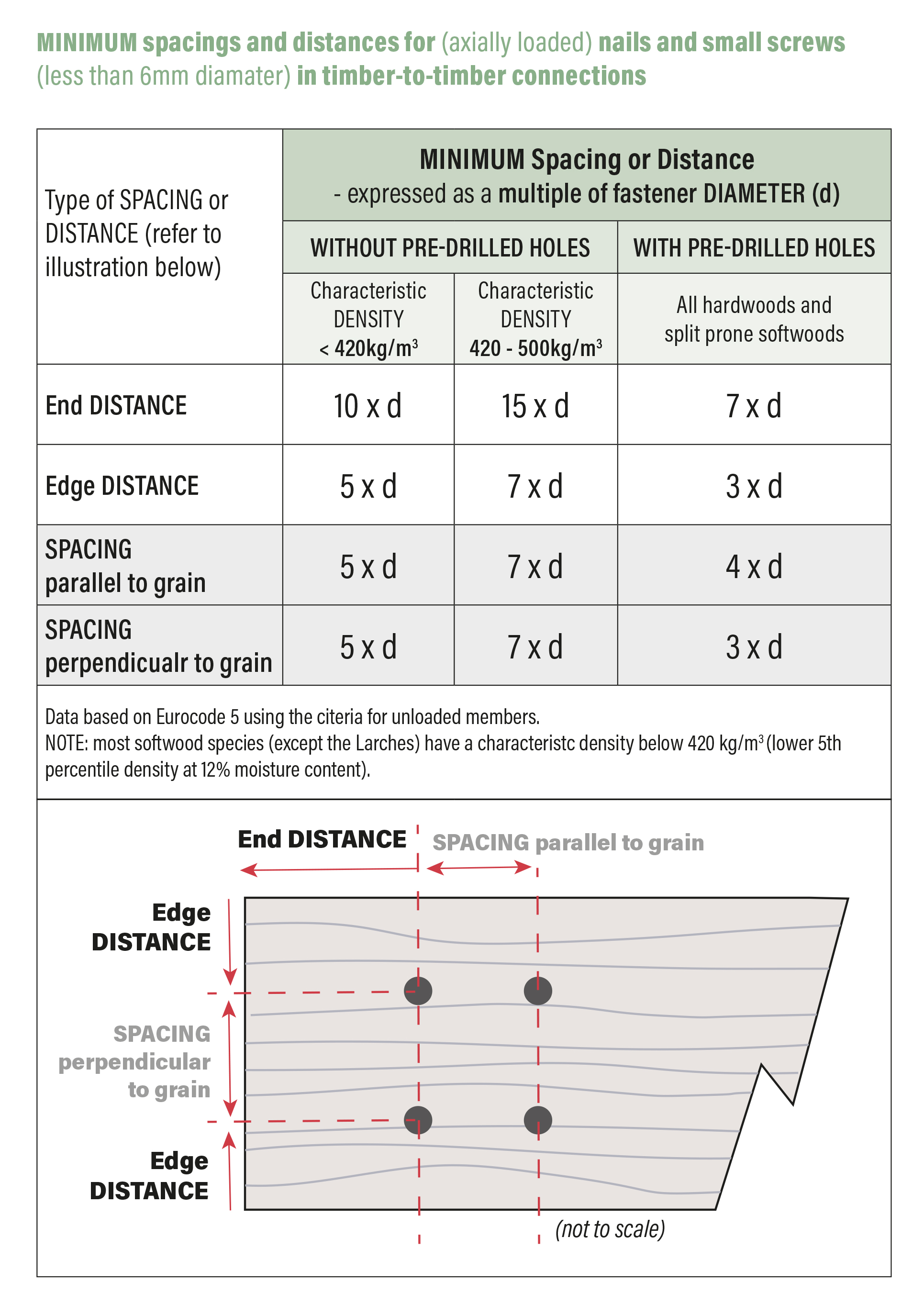

Generic guidance on cladding fixing points to prevent splitting, places them at quarter points of the board width and at least 20mm in from the board end. Here, we give more detailed information on how to determine distances based on the fixing’s nominal shaft diameter and the density of the timber species.

Eurocode 5

BS EN 1995-1-1 (Eurocode 5) sets the standards for timber fixings. Following these requirements is a reliable way of minimising split risks.

You can buy BSI standards at reduced rates HERE.

The standard states that the minimum distance from a fixing to the end of board should be at least 10 times the fastener diameter and with denser, split prone species this is at least 15 times the fastener diameter.

Pre-drilling the fixing holes reduces the split risk and hence the distances required, and is recommended for all hardwoods and dense softwoods.

See our table opposite for more detail.

Away from the board end and edge, splitting is less likely. Parallel fixing spacings are usually set by the position of the battens.

Example of split prone species (Larch)

Using the table and Larch as an example, with a 4mm diameter fixing – the end distance needs to be at least:

-

15 x 4mm(d) = 60mm without predrilling

-

7 x 4mm(d) = 28mm where holes are predrilled

But these are minimum distances and a greater end distance is preferable. It’s common practice to use an end distance of 150mm with larch boards.

Timber types and density

Cladding Wood TypesScrews or Nails?

Cladding Fixings