Open jointed timber cladding: what do I need to know?

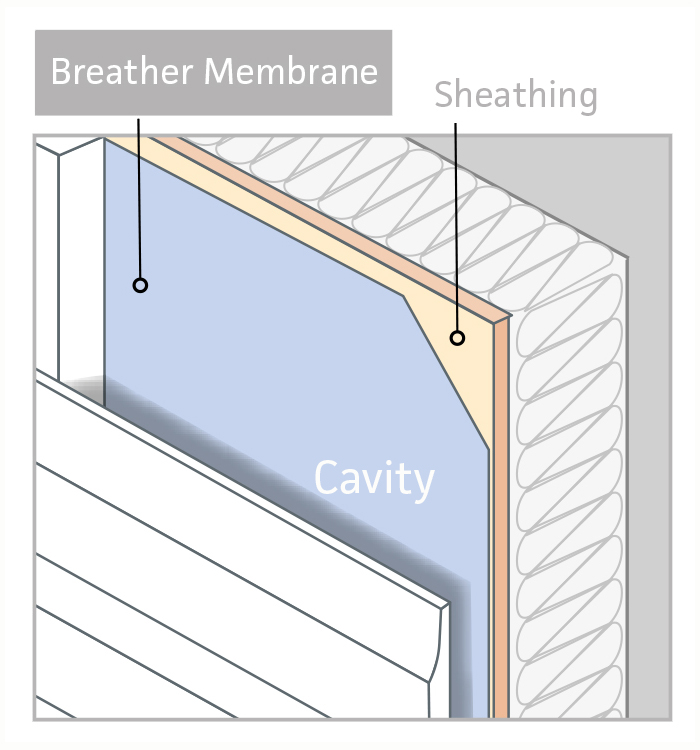

Timber cladding on buildings in the UK is designed and constructed as a rainscreen – providing a building with extra protection against the elements. Any cladding must be separated from the backing wall by a drained and ventilated cavity.

Cavities: moisture and sunlight

Some water will always penetrate the cavity and so the rear face of the cavity needs to be designed as a secondary drainage plane. This plane is usually termed a ‘breather layer’ in the UK and is constructed using a breather membrane or equivalent moisture resistant, but vapour open material. All materials outside of the breather layer should be assumed to be in the wet zone of the building envelope.

Timber cladding can be open or closed jointed, both can perform as a rainscreen although open jointed cladding does have several technical considerations:

-

It allows more rainwater to penetrate the cavity than if the joints are closed and this increases the moisture load on the breather layer.

-

Some types of open jointed cladding allow sunlight to penetrate the cavity; this can photodegrade susceptible breather layer materials such as some types of polymer-based membranes.

-

The open joints can allow people to poke sharp objects into the cavity and thereby damage the breather layer.

-

Most importantly, the fire performance of open jointed timber cladding is generally worse than if closed joints are used. This is because it is impossible to fit a functional cavity barrier within an open jointed cladding assembly – fire can always bypass the barrier through the open joints. Moreover, the open joints expose all board surfaces to the fire.

Recommended by the TDCA and British Standards

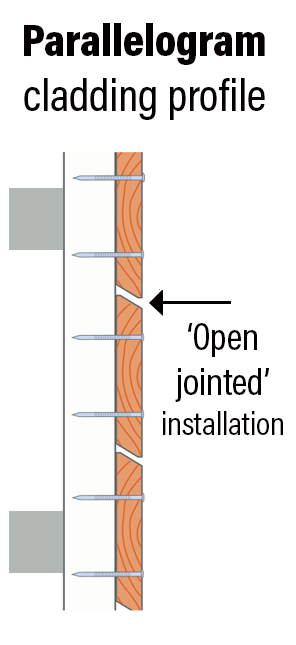

The first 3 risks can be minimized by installing open jointed cladding in a horizontal orientation. This reduces the risk of rainwater and UV penetration of the cavity compared to diagonal or vertical arrangements.

BS 8605-1, the external timber cladding specification standard, lists only ‘horizontal’ as a permitted orientation for open jointed boards and includes chamfering of the board. The profile is described as ‘parallelogram’ in the standard.

TDCA recommends this as the best approach to open joint cladding.

The reaction to fire performance of timber can be improved by the addition of a factory applied and certified flame retardant to the board. Even so, open jointed timber cladding should be restricted to low-rise buildings that are quick to evacuate.

Reduce the risks

If open jointed timber cladding is to be used in a diagonal or vertical orientation, the design needs to ensure that the risks 1 - 3 are reduced as far as possible by:

-

paying particular care to how the breather layer is installed (for drainage);

-

specifying breather layer materials that are resistant to photo-degradation;

-

ensuring gaps between boards are between 8 and 15mm.

Products from Rothoblass

The TRASPIR EVO UV breather membrane product range from Rothoblaas is designed for open jointed cladding. It’s matt black and UV resistant.

The monolithic structure of the membrane guarantees excellent durability over time, thanks to the special polymers used. Twin this with a special tape – Front Band UV210, made from the same material and the system appears invisible behind the façade.

Membrane and tape are fire rated to Euroclass B, S1-d0 (providing the installation is as recommended by the manufacturer). Team these with with specialised Rothoblaas glue products which can fasten the membrane to the wall – better than stapling where building to Passive House Standards are required.

If insect penetration of the cavity is a concern then there is no alternative with open jointed cladding but to cover the whole wall with insect mesh directly underneath the boards. In practice, however, insect mesh is rarely 100% effective and at this scale is susceptible to damage during or after installation. Small insects will always find a way of penetrating the cavity.

Rodent, bird and bat intrusion can be a further concern. Young mice and rats can get through gaps of 6mm and 9mm respectively. Small birds and bats can get through 20mm wide holes. Pest barriers should therefore have an opening gap width of 4 to 5mm – measured as the largest diameter dowel section that can pass through the opening. Reference BRE Digest BR415 gives further guidance.

Mesh should be fixed to support battens according to the manufacturer’s instructions.

A metal vermin mesh such as Rothoblaas Vent Mesh, is always required at the base of cavities near the ground - whether open or close jointed where pest intrusion is a concern. Pest barriers need to be weatherproof, impact and UV resistant.