Decking Fixings

Because wood used out doors is exposed to the weather, metal fixings such as nails, screws, bolts and connectors need to be highly resistant to corrosion.

The consequences of corrosion are unsightly rust stains on exposed components and the possibility that key fixings may fail prematurely leaving the structure unsafe to use.

| Suitable metals | Unsuitable metals |

| Stainless steel (austenitic grade) | Aluminium |

| Silicone bronze | Electro plated metals |

| Carbon steel with a high performance protective coating | Standard uncoated ferrous metals |

| Hot dipped galvanised steel (BS7371:6) | Brass |

| Copper |

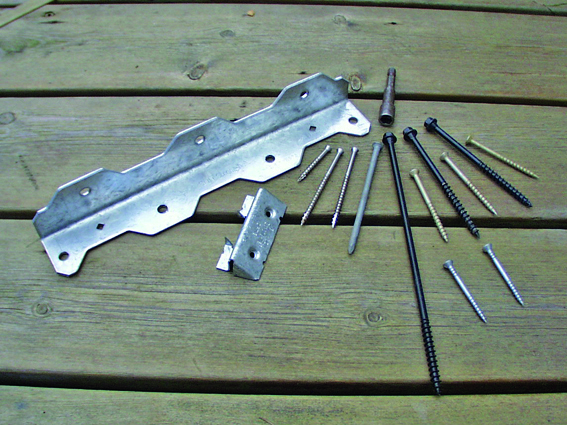

Recommended Deck Board Fixings

Stainless steel annular ring shank nails are economical and less likely than standard nails to pull away, as wood expands and shrinks with the seasons.

Screws provide a number of advantages over nails; they are unlikely to lift if movement takes place in the wood; are more easily removed to allow access to the under deck area; are less likely to be damaged during installation and hammer dents on the boarded surface are avoided.

On hardwoods or dense species softwoods, the use of screws is always recommended. Pre-drill pilot holes with 2mm oversized clearance and countersink slightly below the surface.

A number of specialised decking screws are available. They include features such as self-drilling threads, self-countersinking heads and optional protective coatings. Some designs are suitable for driving straight into wood without the need for pilot hole drilling. Always follow the manufacturer’s installation instructions.

All fixings should be between 2-3 times the length of the board thickness (unless the fixing manufacturer can substantiate any different).

Substructure Fixings

Where strength and safety is critical:

Bolts should be 25mm longer than the combined width of the components being joined. For best results, particularly on visible fixing points, use dome headed carriage bolts which are self-anchoring when tightened.

When fixing ledger boards or wall plates to a building, expanding or chemically secured anchor bolts are recommended.

Landscape screws come in a variety of styles and are extremely useful if only one side of a component is accessible.

The use of pre-formed connectors not only makes deck construction easier it also strengthens the joint between one component and another significantly and prevents any splitting of wood or weak points that can occur if only nails or screws are used.

Connectors are available for almost any situation where timber components are joined. The most widely used connectors for deck construction are joist hangers, joist ties and post anchors. The fixings used to install these connectors should be made from the same metal as the tie itself to prevent metal corrosion.

Look for Products with the Mark

Third-party product quality accreditation TDCA DeckMark.

Learn more about Metal Fixings

Technical Bulletin TB08Source a Supplier

Suppliers