Chimney flues and timber clad walls: what do I need to know?

Chimneys and flues connected to combustion appliances get hot. Their passage through a timber cladding assembly needs careful detailing to cope with thermal expansion and the risk of fire in the external wall.

Unfortunately no up-to-date standard details are available for this assembly, but we will outline the present guidance under Current Standards further down this FAQ.

Building Regulations

ENGLAND

All installations should conform to the applicable Building Regulations, which are set out in Approved Document J (H.M. Government, 2022), or adopt the recommendations of the standards listed therein.

Page 52 of Approved Document J recommends that:

- Combustible materials in the building fabric should be protected from the heat dissipation from flues so that they are not at risk of catching fire…

- Where a fluepipe or chimney penetrates a fire compartment wall or floor, it must not breach the fire separation requirements of … Approved Document B.

- Flues should be at least 25mm from any combustible material (measured from the outer surface of the flue wall, or the outer surface of the inner wall in the case of multi-walled products).

- Where passing through a combustible wall, floor or roof (other than a compartment wall, floor or roof) this separation can be achieved by a non-combustible sleeve enclosing the fluepipe or chimney with a 25mm air-space to the relevant flue wall. (The air- space could be wholly or partially filled with non-combustible insulating material).

SCOTLAND

Section 3.19 of the Scottish Building standards technical handbook (Scottish Government, 2022) gives similar guidance:

- There should be a separation distance where a metal chimney passes through combustible material. This is specified, as part of the designation string for a system chimney when used for oil or gas, as (Gxx), where xx is the distance in mm. Where no data is available, the separation distance for oil or gas applications with a flue gas temperature limit of T250 or less should be 25mm from the outer surface of a single-walled chimney to combustible material. The 25mm should be measured from the surface of the inner wall of a double-walled chimney. There is no need for a separation distance if the flue gases are not likely to exceed 100ºC.

- There should also be a separation distance where the metal chimney runs in close proximity to combustible material. The separation distance should be 25mm from the outer surface of a single-walled chimney to combustible material. The 25mm should be measured from the surface of the inner wall of a double-walled chimney. There is no need for a separation distance if the flue gases are not likely to exceed 100ºC.

- To prevent the possibility of radiated heat starting a fire, a flue-pipe should be separated from combustible material by:

- a distance according to the designation of the flue-pipe in accordance with BS EN 1856-2: 2005, or

- a distance equivalent to at least 3 times the diameter of the flue-pipe. However this distance may be reduced:

- to 1.5 times the diameter of the flue-pipe, if there is a non-combustible shield provided in accordance with the following sketch, or

- to 0.75 times the diameter of the flue-pipe, if the flue-pipe is totally enclosed in non-combustible material at least 12mm thick with a thermal conductivity of not more than 0.065W/mK.

_________________________________________________________

Current Standards

The current standards are out-of-date and are due to be revised:

- BS EN 15287-1:2007+A1:2010 (BSI, 2010)

prBS EN 15287-2 (BSI, 2021) [DRAFT FOR DEVELOPMENT] - TRADA Manual: Lancashire and Taylor (2011).

The regulatory guidance in Scotland and England mirrors that in BS EN 15287-1:2007+A1:2010 and BS EN 15287-2, these standards note that:

- The manufacturer has a responsibility to declare the safe distance to a combustible material, and a recommended installation detail.

- Where no data is available, the separation distance for oil or gas applications with a flue gas temperature limit of 250°C or less should be 25mm from the outer surface of a single-walled chimney to combustible material. The 25mm should be measured from the surface of the inner wall of a double-walled chimney.

- There is no need for a separation distance if the flue gases are not likely to exceed 100°C.

Additionally, they recommend that:

- Metal flues and chimneys should be wrapped in a flexible sleeve that allows the chimney to expand with heat without compromising the weathertight seal or damaging the surrounding timber boards.

- At the appliance’s rated output, the temperature of adjacent combustible materials – in this instance, timber – should never exceed 85°C when related to an ambient temperature of 20°C.

BS EN 15287-2 is being updated and the latest draft (BSI 2021) recommends that:

- Connecting flue pipes for combustion appliances with maximum temperatures between 85 °C and 160 °C should be at a minimum distance of 50mm from combustible materials, when installed in free ventilated conditions.

- Free ventilated metal connecting flue pipes for temperatures higher than 160 °C shall either be installed at a minimum distance to combustible materials of at least three times their nominal diameter but not less than 375mm or the distance specified in the national regulation.

- The minimum distance to combustible material may be reduced to 1,5 times the nominal diameter but not less than 200mm, if a radiation shield ventilated on both sides, made from non-combustible material, is installed between the connecting flue pipe and the adjacent combustible materials.

- The minimum distance to combustible material may be reduced to 100mm, if the connecting flue pipe has a free ventilated non-combustible thermal insulation with at least 20mm thickness and a minimum thermal conductivity of 0,04 m²K/W (at 20 °C).

(BSI 2021 p.101)

The 5th edition of TRADA’s Timber Frame Construction Manual (Lancashire and Taylor, 2011) gives additional recommendations although some of these are now quite dated:

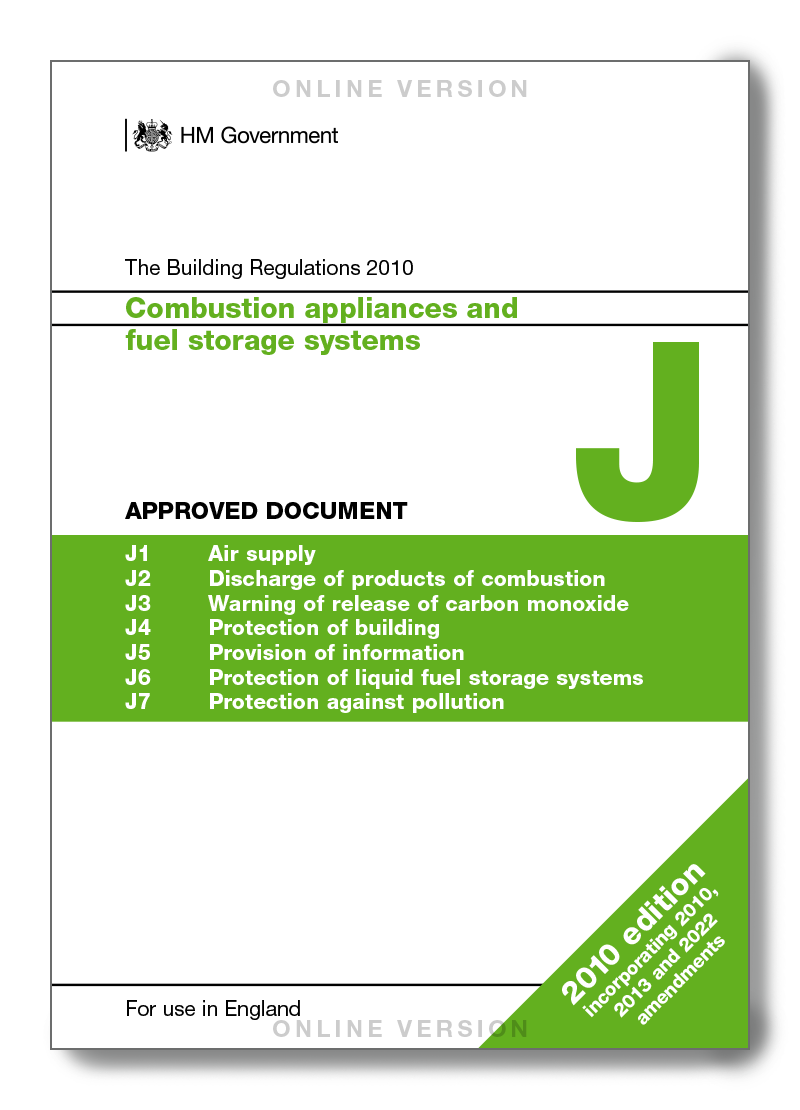

- A room sealed chimney system terminal, passing through the timber frame wall, requires careful detailing and installation. The outlet passing through the wall should be surrounded by a sleeve of non-combustible material, such as metal or non-combustible board, with:

- a gap of not less than 25mm for a concentric room sealed system and the combustible material when serving a natural draught

- a gap of not less than 10mm when serving a fanned draught or condensing appliance

- a gap of not less than 10mm for a condensing appliance with separate air supply and flue duct, and zero for the corresponding air supply duct.

- The gap should be sealed to prevent excessive air penetration with an internal lining of non-combustible board or by packing the inner side with mineral wool. Some types of room sealed chimney systems incorporate a seal between the appliance backplate and the internal wall lining, obviating the need for an additional seal.

- If the external wall cladding is of combustible material, use a metal or other non-combustible face plate to maintain the terminal in position and protect the cladding ... This plate should extend at least 50mm beyond the edge of the flue terminal flange and a greater projection may be advisable to avoid damage to painted claddings. The flue terminal manufacturer’s advice should be sought.

Lancashire and Taylor (2011) p.202

TRADA’s manual (currently being revised) gives the following generic detail for a flue to a room-sealed appliance penetrating a timber-framed and clad wall.

Cavity barriers should be provided in the external wall cavity and must be installed as required around openings in the cavity. The cavity barriers extend vertically down the sides of the flue opening to isolate the concealed space.

As already noted, this guidance might be out of date and is likely to be affected by the forthcoming update to BS EN 15287-2.

References

BS EN 15287-1:2007+A1:2010. Chimneys – Design, installation and commissioning. Part 1: Chimneys for non-roomsealed heating appliances. London, British Standards Institution.

prBS EN 15287-2 Chimneys - Design, installation and commissioning. Part 2: Chimneys and connecting flue pipes for room sealed combustion appliances. London, British Standards Institution. [DRAFT FOR DEVELOPMENT]

Lancashire, R. and Taylor, L. (2011) Timber frame construction - Designing for high performance. 5th edition. High Wycombe, TRADA Technology.

H.M. Government (2022) The Building Regulations 2010. The merged approved documents for use in England. Part J Combustion appliances and fuel storage systems. London, Ministry of Housing, Communities and Local Government.

Scottish Government (2022) Building standards technical handbook 2022: domestic. Section 3: Environment. Edinburgh, Local Government and Housing Directorate.