Is composite decking all it's cracked up to be?

Monday, May 26, 2025

Almost all outdoor decks are built using timber for structural support. But, when it comes to the deck surface, there is a choice to be made.

Preservative pre-treated softwoods remain the most cost-effective and sustainable choice for deck frames and deck boards whereas those with more budget flexibility can opt for more visually appealing, harder wearing deck surfaces made from hardwood. There’s also the option of man-made deck boards made from a combination of wood cellulose powder and thermo-plastic polymers, known as wood plastic composites (referred to as composites throughout this blog).

Composite deck boards are now available from just about every DIY superstore or Builders Merchants in many different colourways and visual looks. Numerous different brands have emerged over the last decade to challenge the popularity of timber deck boards.

There is no universal formula for the wood powder and plastic mix which means the performance of composites can (and do) differ. Whilst all manufacturers special-plead for their own composite brand, the key marketing message from makers is that extruded composite decking is better than timber because it’s slip resistant and does not warp, crack, splinter or require staining or sealing during its service life.

Verifying performance claims

The last ten years has seen the number of composite brands increase dramatically. TDCA recognised that performance claims were not subject to independent verification using consistent procedures. “There is a long history of independent wood science, technical data and British Standards behind the specification and use of timber for decks; but when it comes to composite materials a manufacturers declaration of performance is often all you’ll get.“ says TDCA director Janet Sycamore who explains that because composites are artificially produced and endure various environmental conditions during service, it is vital they meet consistent performance and production criteria - just like timber has to.

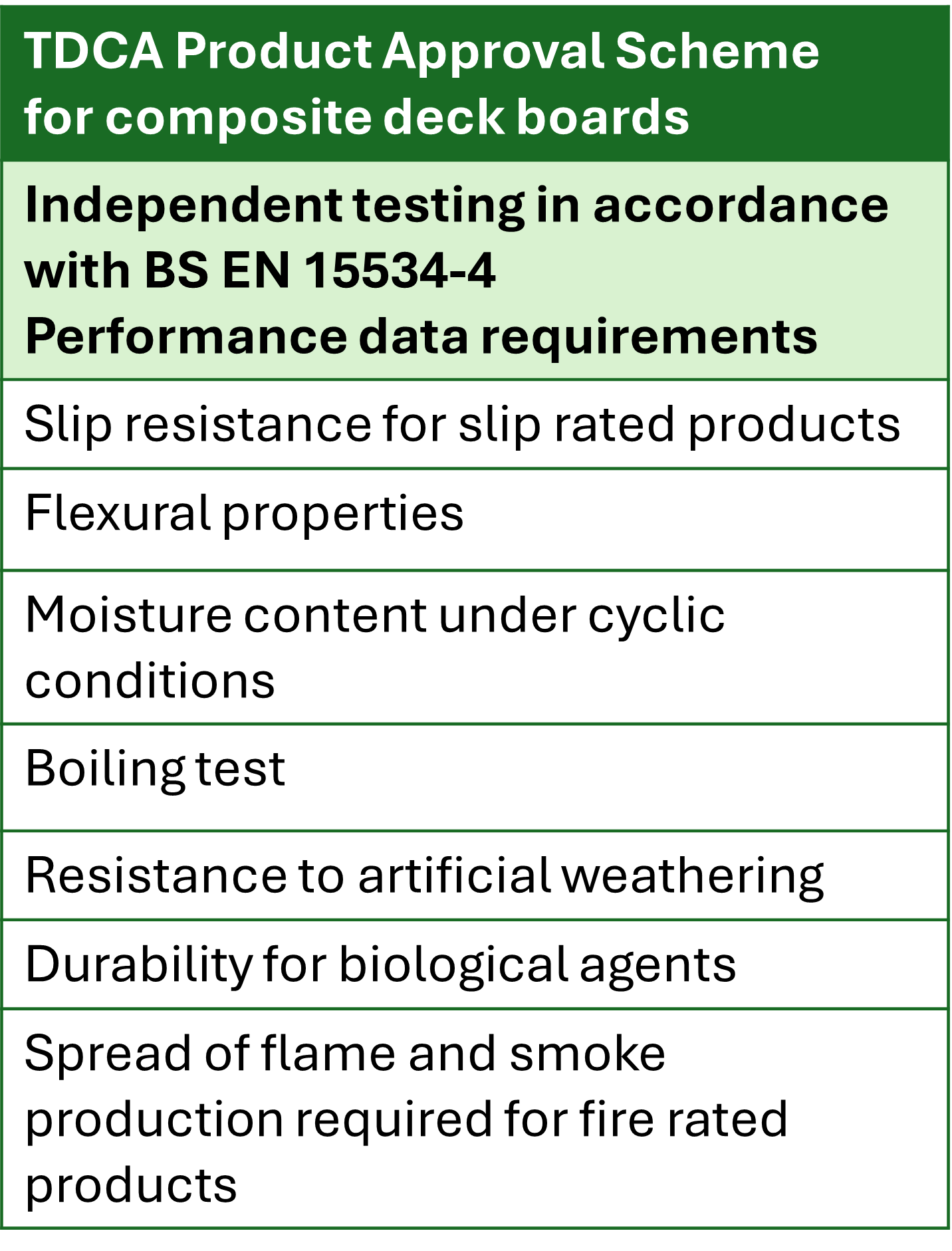

Product Approval Scheme for composites

The lack of comparable performance data lead the TDCA to introduce a Product Approval Scheme (PAS) for composite deck boards in 2019. The scheme was developed in consultation with an advisory committee made up of composite decking manufacturers and independent experts. At the heart of the scheme is BS EN 15534-4 2014 which provides test methods to determine the durability of decking made from composite materials and verify strength, and resistance to weathering, moisture, biological agents and other performance qualities such as fire resistance.

Manufacturers were so confident that the PAS would help differentiate serious producers of composite deck boards from opportunists taking advantage of a market trend that they agreed PAS compliance should be a requirement for full membership of the TDCA.

“In 2019 we were had an initial flurry of applications from composite decking manufacturers seeking the credibility of this TDCA endorsement of performance.” says Janet who confirms that at the time of writing this article five years after the PAS was launched, not one board made from a composite material has achieved certification. "The scheme would definitely help buyers identify quality brands” says Janet.

What the TDCA knows about composites

The TDCA has a lot of experience of composite deck boards under its Expert Opinion Report Service. Here is a summary of some of what the TDCA has learned:

1.Colour fade

Composite decking is not immune to the ultra-violet rays of sunlight. Like most coloured materials, many brands of composite decking have issues with colour fade and discolouration over time. Some manufacturers provide anti fade warranties.

2. Warping

Materials made largely from plastic become softer when the weather gets hotter. This means that composite decking can warp and become distorted during hot weather and direct sunlight. This is why the timber joists supporting most composite deck boards must be installed at much closer centres than for timber decking. Be sure to check spanning capabilities of the products you are considering.

3. Surface mould and mildew

Like any outdoor surface composite decking is susceptible to mould and mildew growth, particularly in damp and shaded areas. Boards laid with an inadequate drainage fall can lead to water accumulation. Water doesn’t readily absorb into plastic, it stagnates, leading to mildew, mould and moss growth which are a slip hazard. Regular surface cleaning of composite deck surfaces is essential. Always follow good practice installation and maintenance guidance.

4. Cracking

Because it’s an inert material composite decking is dimensionally stable but factors like incorrect installation, an inadequate support structure or exposure to extreme temperatures can cause some composite deck boards to crack or become brittle and fracture. Again always follow good practice installation guidance.

5. Buyers should be cautious

Composite deck boards are not cheap and experience shows that there is considerable variation in the formulation of the composite material which can impact the quality of its behaviour in service. The TDCA’s product approval scheme for composite decking was intended to help guide buyers in selecting a board that would meet their expectations for quality and performance. With no approved products currently, buyers are advised to be cautious and do their own due diligence on the product they are thinking about using.