Don’t Risk Your Timber Cladding – Choose the Right Battens

Wednesday, January 14, 2026

When it comes to installing external timber cladding, battens might not be the first thing you think about - but they’re one of the most critical components of the whole installation. Get them wrong, and even the best-quality cladding won’t perform as it should.

One of the most common mistakes we see is the assumption that roofing battens can double up as cladding battens. They can’t. Here’s why the difference matters and how to make sure you’re using (or selling) the right type every time.

Roofing vs Cladding Battens: What’s the Difference?

Although they might look similar, roofing battens and cladding battens face very different environments and face different exposure conditions.

Cladding battens are classified in British Standards as external applications as they are potentially exposed to moisture entering behind the rainscreen. They are typically made from low durability softwood therefore, they need to be pressure-treated to Use Class 3 to withstand that environment. Roofing battens are treated to a lower level of protection as they are classed as Use Class 2 applications for internal building use and so aren’t designed for such exposure conditions and shouldn't be used in their place.

Using the wrong type of batten could seriously compromise the durability and safety of your cladding installation - so it’s vital to check what you’re working with.

Photo caption: The blue colour is a signal that these are roofing battens.

What Makes a Good Cladding Batten?

Look for pressure-treated softwood, such as pine or spruce, that offers a desired service life of at least 30 years.

Always ask for a treatment certificate confirming both the Use Class and intended desired service life - these should ideally match the performance and longevity of your chosen cladding boards.

Vertical or Horizontal?

The batten arrangement depends on the direction of your cladding:

For horizontal cladding, use vertical battens (typically 50x38mm or 50x25mm if there’s no side jointing).

For vertical cladding, add horizontal counter battens to maintain good ventilation and drainage. These should be at least 50mm wide and 25mm thick.

Click on images to expand.

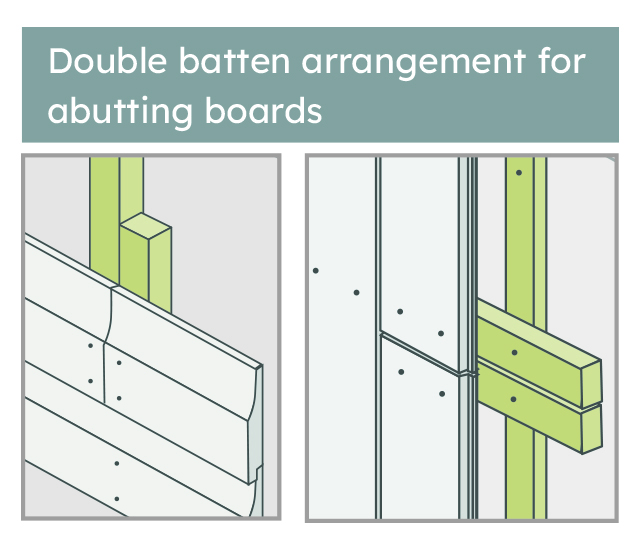

Connecting Double Battens at Board Joints

Where cladding boards abut, a double batten arrangement is recommended to reduce the risk of splitting and to provide adequate fixing support. This is achieved by fixing an additional short length of batten alongside the main batten at the board joint.

To ensure good performance and durability, the additional batten should be sized and fixed correctly. Assuming standard batten sizes (as referenced earlier), fixings should typically be 2.8 – 3.8 mm in diameter and 75 – 100 mm in length. The supplementary batten should extend around 100 mm beyond the width of the cladding board being butt jointed, ensuring sufficient fixing area for both boards.

This simple detail helps maintain fixing integrity at joints and supports long-term performance of the cladding system.

Do Battens Need a Sloping Top?

Some suppliers now offer battens with a sloped or chamfered top edge to help shed water into the cavity. While this is a sensible “belt-and-braces” measure, we are not aware of any conclusive evidence that it significantly improves performance.

Strength Grading and Timber Species

Cladding battens aren’t strength-graded in the same way as structural timbers. Instead, they’re usually visually sorted to exclude large knots, splits or decay, or sometimes graded in accordance with BS 5534 (the roofing batten standard), although this isn’t a strength-grading standard as such.

Common species for cladding battens include UK-grown larch, pine and spruce, or imported equivalents as defined under BS 5534. These species all have a minimum mean density of 350 kg/m³ (at 12% moisture content), ensuring good fixing strength for cladding fasteners.

When specified in line with BS 5534 – Code of Practice for Slating and Tiling (including Vertical Cladding) – your battens will meet the engineer’s minimum density requirements.

Supporting Best Practice

At the Timber Decking and Cladding Association (TDCA), we’re passionate about promoting good practice and fit-for-purpose products for external timber applications. Too often, issues arise simply because the wrong materials were chosen or installed incorrectly.

By ensuring the right battens are used, you’re not just supporting a better build - you’re helping protect the reputation of timber as a durable, sustainable and high-performing construction material.

Supporting Best Practice

You can find practical information in The Timber Cladding Handbook, freely available online. We also offer an advisory service for unanswered queries – use the Contact Us form to submit any questions.

For more details, refer to BS 8605 External Timber Cladding Part 1 - Method of specifying, designed to help manufacturers and specifiers. TDCA offers a 15% discount to purchasers.